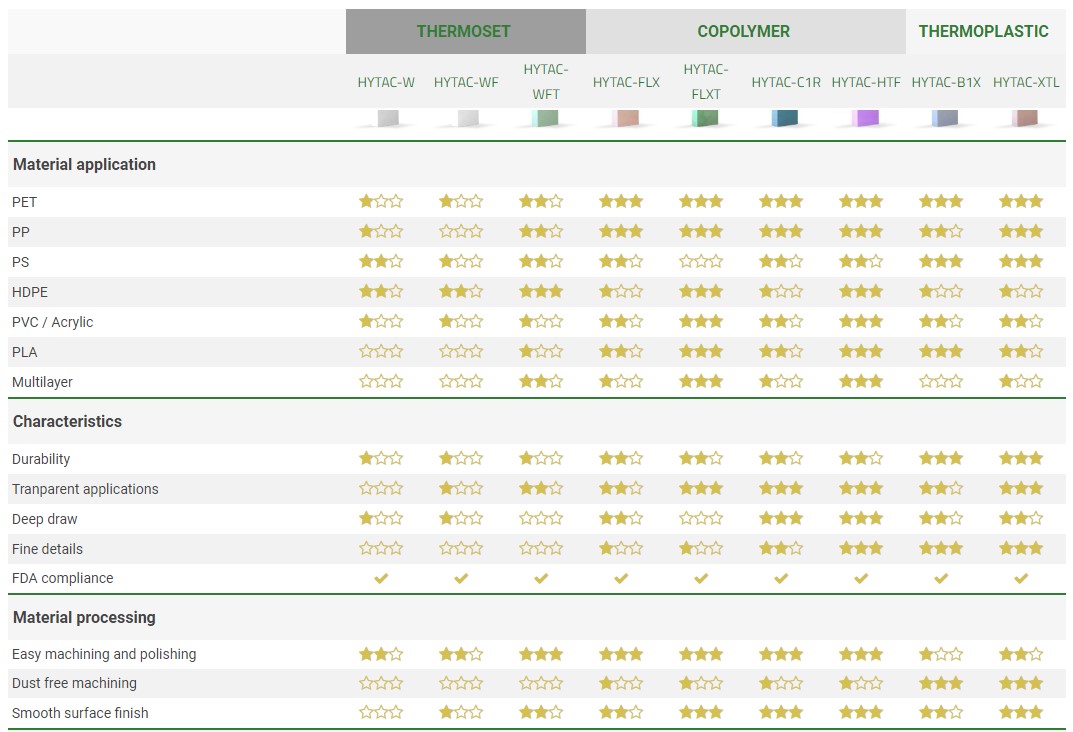

HYTAC®-FLX HYTAC®-FLX

FLX – Specifically blended to minimize chilling of the sheet, optimize plug/sheet interaction and provide uniform material distribution in a toughened plug. Suitable for a wide range of polymers. Rapid machining and easy polishing.

|

|

HYTAC®-FLXT HYTAC®-FLXT

FLXT – The best choice for forming multilayer or barrier film materials. Combines the properties of FLX with PTFE impregnation to minimize the chance of sheet stick or scratch. Polishes to a mirror-like surface.

|

HYTAC®-C1R HYTAC®-C1R

C1R – Formulated with friction enhancers and tougheners for deep draw or challenging geometry applications. Polishes to a mirror-like surface to further enhance friction.

|

|

HYTAC®-HTF HYTAC®-HTF

HTF – High temperature, high friction, high toughness, easily machined and polished to ensure high performance in demanding applications.

|